sonyachnі stantsії

near the Dnipro region

→ Стойки каркаса: С-профиль 100*50*12*2,0 мм или 120*40*10*2,0 мм;

→ Раскосы для опорных стоек: П-образный профиль 41*41*1,5 мм;

→ Направляющие профиля: П-образный профиль 41*41*1,5 мм или 41*62*2,0 мм;

→ Фурнитура для крепления конструкции – оцинкованная сталь;

→ Хомуты – алюминий АД-31;

→ Прокладки – композитный алюминий;

→ Модули крепления фурнитуры – нержавеющая сталь А2.

Material manufacturingRetail price

Material manufacturingRetail price

Material manufacturingRetail price

*prices are indicated in hryvnias

Material manufacturingRetail price

Material manufacturingRetail price

Material manufacturingRetail price

*prices are indicated in hryvnias

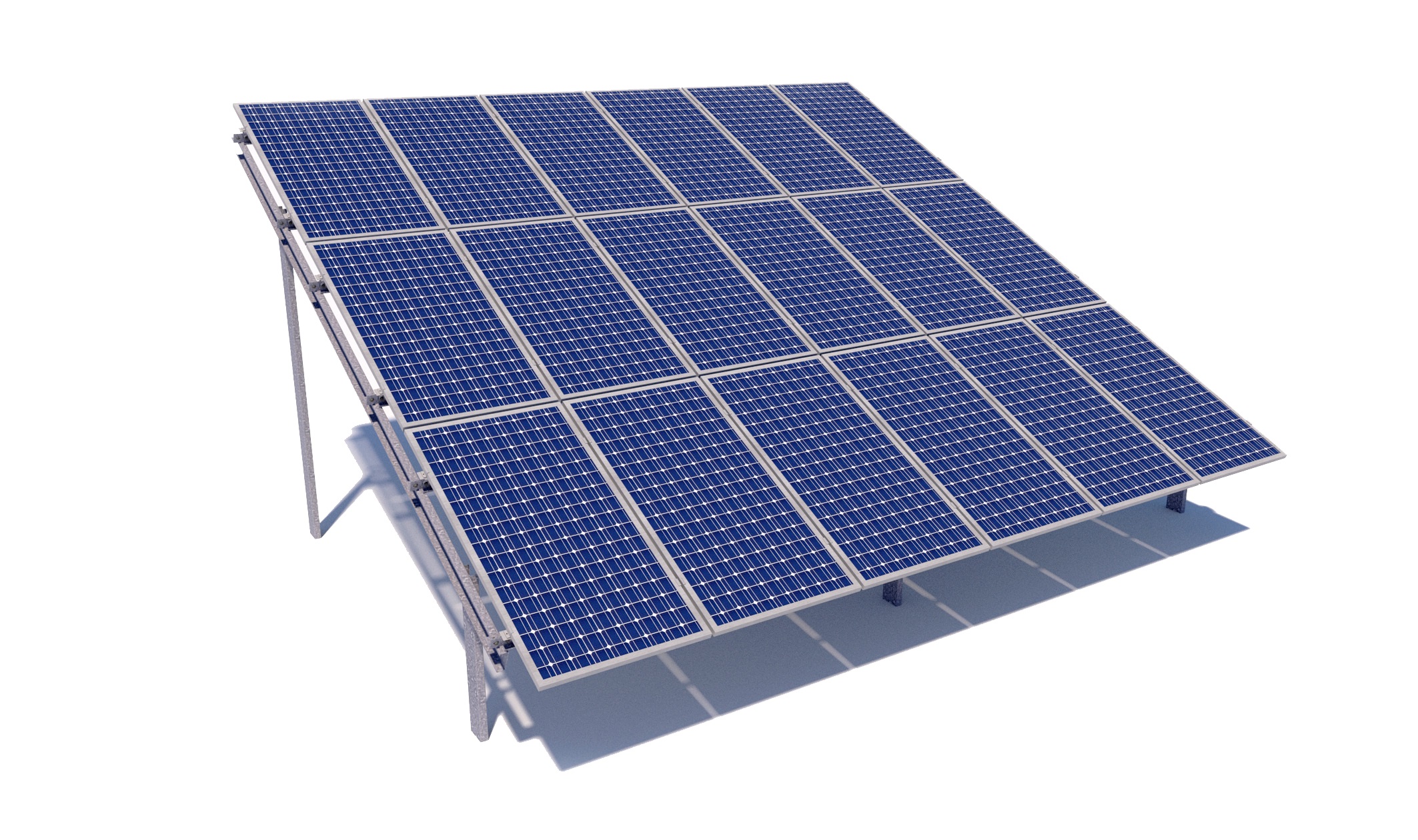

Наземные сооружения для солнечных панелей являются оптимальным вариантом для размещения крупных электростанций . Важно подготовить обширную территорию под застройку, разработав детальный проект комплекса. Необходимо учитывать мощность электростанции, месторасположение участка, особенности рельефа и климата.

Какие преимущества рельефа местности следует учитывать перед установкой наземных конструкций солнечных электростанций:

– территория минимально затенена;

– холмы и склоны, которые можно использовать для повышения эффективности солнечной электростанции;

– возможность оптимального выбора ориентации панелей.

К наземным конструкциям солнечных модулей должен быть обеспечен свободный доступ технического персонала , к каждому фотоэлементу комплекса.

Монтаж солнечных панелей на земле предусматривает различные конструкции:

– для стационарных – выбирают оптимальный угол наклона для максимального поглощения солнечной энергии;

– динамических – разворачиваются вслед за движением солнца.

У нас вы можете купить оптимальные наземные крепления для солнечных панелей с учетом технических условий и особенностей земельного участка.

Горячеоцинкованный профиль для наземной системы крепления солнечных батарей: – производится профилирование, затем перфорация, в конце готовый профиль погружается в ванну для горячего цинкования, поэтому его и называют «горячий цинк», в результате получается монолитная и сплошная обработка всей поверхности профиля, что обеспечивает максимальную защиту от внешней среды и долгий срок службы наземных систем крепления солнечных батарей.

– Направляющий профиль – сталь 08пс., конструкционная углеродистая, высококачественная, горячеоцинкованное покрытие толщиной 50-70 мкм = 800-900 грамм цинка на 1 кв.м. металла;

– Хомуты для крепления модулей – алюминий;

– Кронштейны – оцинкованная сталь;

– Строительный крепеж – оцинкованная сталь;

– Теплоизоляционные прокладки – композитный алюминий;

– Метизы алюминиевых хомутов для крепления модулей – нержавеющая сталь А2.

Холоднооцинкованный профиль для наземного монтажа солнечных панелей: – профилирование, а затем перфорация производятся из предварительно оцинкованного металла, в результате чего все отверстия и торцы профиля не покрыты цинком и, соответственно, подвержены коррозии.

– Направляющий профиль – сталь 08пс + цинковое покрытие ZN275 25 мкм = 275 грамм цинка на 1 кв.м. металла;

– Клипсы крепления модулей – алюминий;

– Кронштейны – оцинкованная сталь;

– Строительный крепеж – оцинкованная сталь;

– Теплоизоляционные прокладки – композитный алюминий;

– Комплектующие алюминиевых хомутов для крепления модулей – нержавеющая сталь А2.

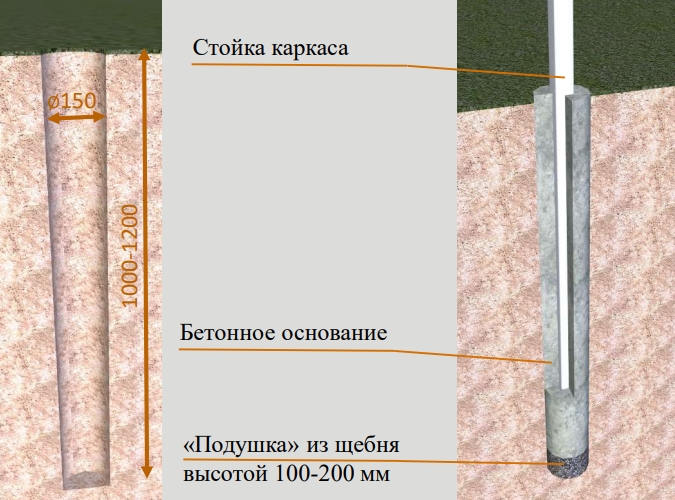

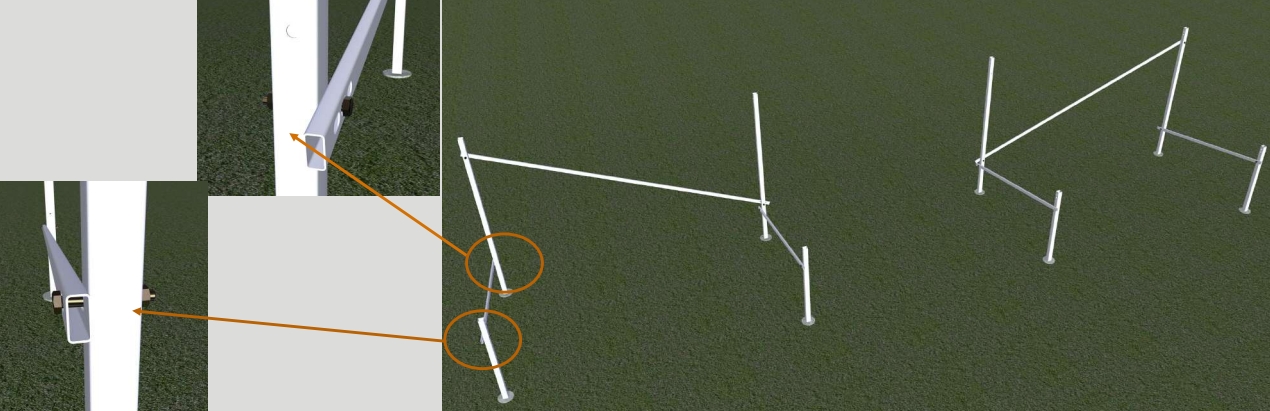

Шаг 1: Установите каркасные стойки на бетонный фундамент.

В начале монтажа в грунте делается котлован под будущий фундамент стойки каркаса. В основании котлована делается подушка из щебня средней фракции, после чего в котлован устанавливается стойка и заливается бетоном. В качестве стоек каркаса используется квадратная профильная труба 50х50х2.

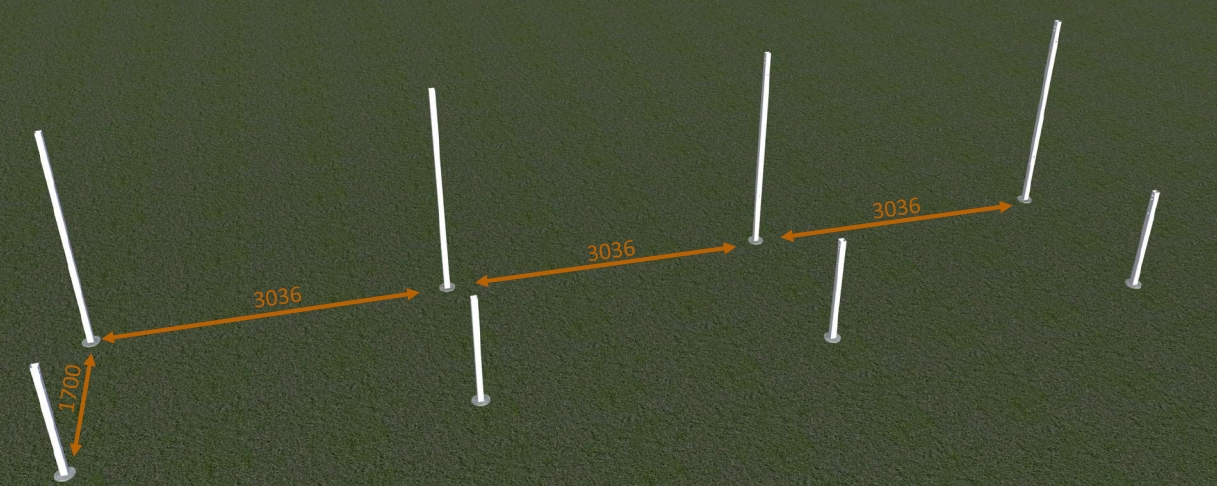

Передние и задние стойки рамы расположены на расстоянии 1700 мм друг от друга. Расстояние между рядами стоек составляет 3036 мм.

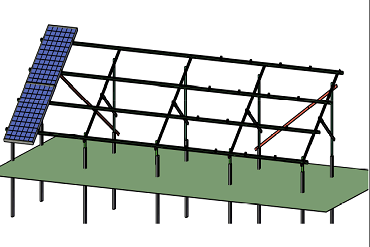

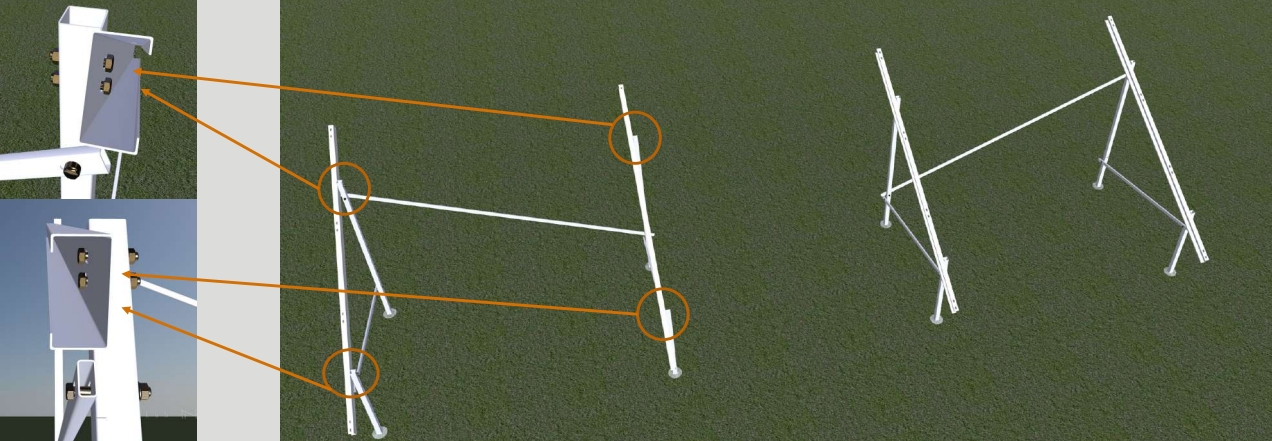

Шаг 2: Установка опорной рамы на столбы

После бетонирования фундаментов передние и задние стойки соединяются между собой квадратной профильной трубой 40х20х2, с помощью шестигранных болтов, установленных в предусмотренные отверстия. На крайних задних стойках таким же образом устанавливаются распорки из квадратной трубы 40х20х2.

В верхней части опорных стоек с помощью болтов с шестигранной головкой крепится С-образный опорный профиль.

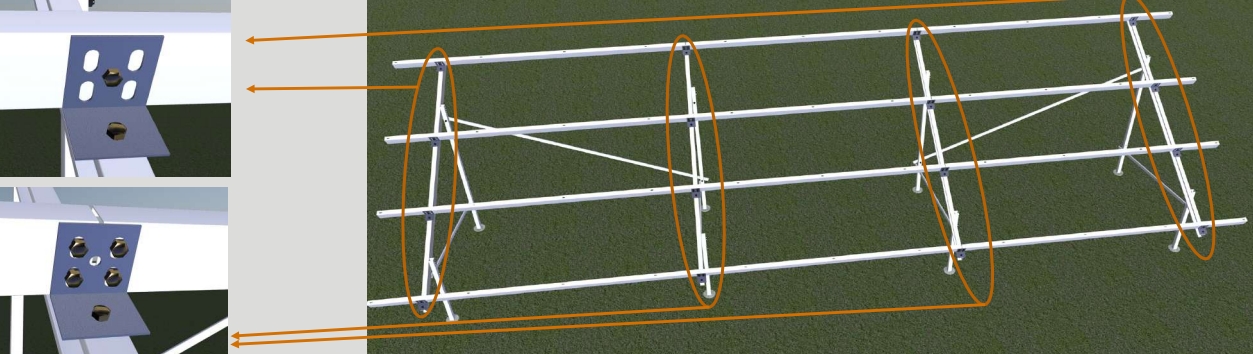

Шаг 3: установите направляющий профиль на стойки каркаса

На несущий С-образный профиль с помощью уголков крепится направляющий С-образный профиль, на который впоследствии устанавливаются солнечные панели. Крепление на каркас осуществляется болтами с шестигранной головкой в предусмотренные отверстия. По краям конструкции направляющий профиль крепится к уголку одним болтом, на внутренних рядах стоек, где уголок также выступает в качестве соединителя отдельных элементов профиля, крепление осуществляется 4 болтами.

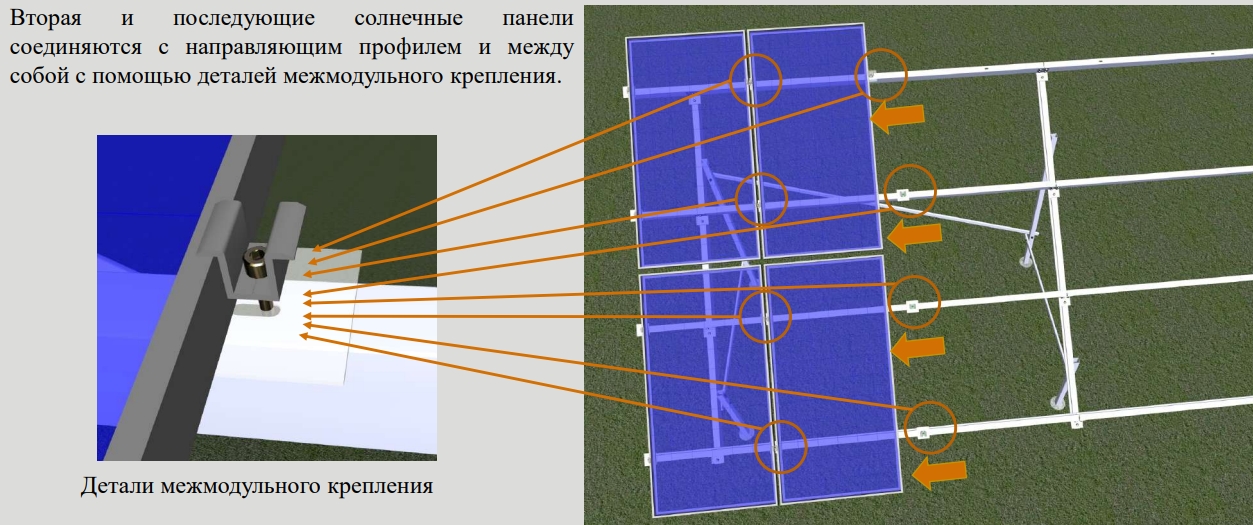

Этап 4: установка солнечных панелей на рельсы

Солнечные панели Edge крепятся с помощью краевых крепежных деталей. Краевые крепежные детали устанавливаются на направляющий С-профиль с помощью полного болтового соединения в предусмотренных овальных отверстиях. После установки панели в краевые крепежные элементы затягиваются крепежные винты, фиксируя солнечную панель.