sonyachnі stantsії

near the Dnipro region

→ Guide profile 41x41x9x8x1.5 mm – hot-dipped galvanized steel 50-70 microns, cold-galvanized steel 25 microns;

→ Brackets – hot-dip galvanized steel 50-70 microns;

→ Hardware for fastening the structure – galvanized steel;

→ Clamps – aluminum AD-31;

→ Gaskets – composite aluminum;

→ Hardware fastening modules – stainless steel A2.

| Material of manufacture | Super-OPT | OPT | Retail |

| Hot zinc ULTRA | 455 | 510 | 555 |

| cold zinc | 375 | 425 | 460 |

| Aluminum | 645 | 720 | 785 |

*prices are indicated in hryvnias

Mounting solar panels on a pitched roof is designed to fix the photovoltaic modules in the required position. Mounting systems for solar panels on a pitched roof must be reliable and durable.

Aluminum alloy mounts, which can be purchased on our website, will last you at least 25 years.

Thanks to anodic oxidation – mount for solar panels on the roof is not exposed to moisture, ultraviolet radiation and is resistant to mechanical stress.

It is important to choose the right angle of inclination of solar panels on a flat roof, taking into account the geographic latitude of the area.

Here you can buy high-quality mounts for solar panels on a pitched roof, thanks to which you will securely and firmly fix the modules.

We offer favorable prices and delivery throughout Ukraine.

The ULTRA Hot Dip Galvanized Pitched Roof Solar Mount Treatment System is a certified anti-corrosion hot dip galvanizing according to ISO1461:2009.

This coating protects metal products from steel from corrosion for more than 30 years.

Profiling is then perforated, at the end the finished profile is immersed in a hot zinc coating bath, which is why it is called “hot zinc”.

The result is a monolithic and continuous processing of the entire surface of the profile, which provides maximum protection from the external environment and a long service life of the solar panel mounting system on a pitched roof.

– Guide profile – 08ps steel, structural carbon, high-quality, hot-dip galvanized coating 50-70 microns thick = 800-900 grams of zinc per 1 sq.m. metal;

– Clamps for fastening modules – aluminum;

– Brackets – hot-dip galvanized steel;

– Construction hardware – hot-dip galvanized steel;

– Insulating gaskets – composite aluminum;

– Hardware for aluminum clamps for fastening modules – stainless steel A2.

Cold-galvanized processing system for fixing solar panels on a pitched roof: Produced from pre-galvanized metal, profiling is then perforated, and as a result, all holes and ends of the profile are without zinc coating and corrode accordingly.

– Guide profile – steel 08ps + ZN275 zinc coating 25 microns = 275 grams of zinc per 1 sq.m. metal;

– Clips of fastening of modules – aluminum;

– Brackets – galvanized steel;

– Construction hardware – galvanized steel;

– Insulating gaskets – composite aluminum;

– Hardware for aluminum clamps for fastening modules – stainless steel A2.

– Guide profile – aluminum;

– Clamps for fastening modules – aluminum;

– Brackets – aluminum + stainless steel A2;

– Construction hardware – stainless steel A2;

– Hardware of aluminum clamps for fastening modules – stainless steel A2.

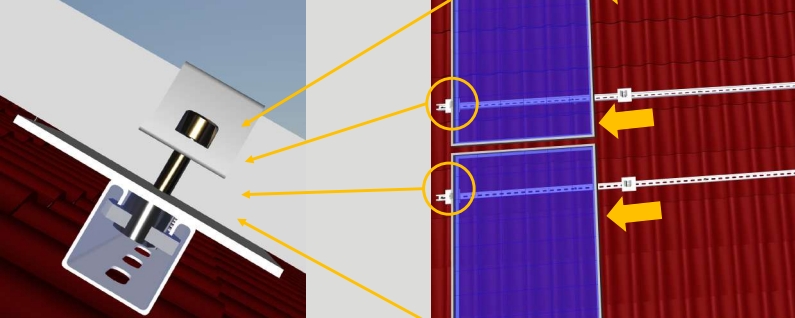

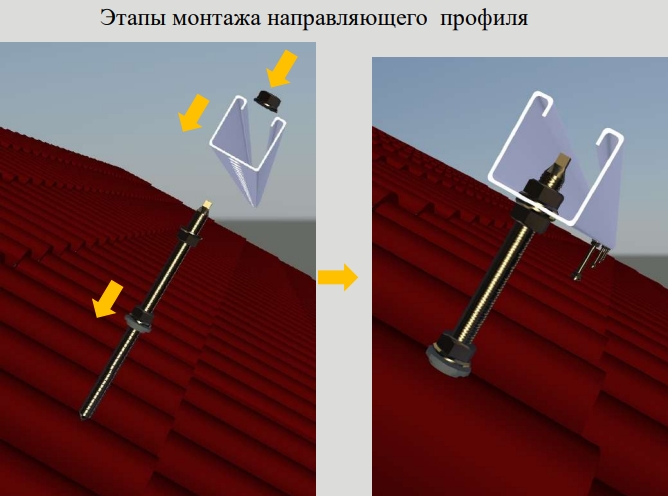

Stage 1: Attaching the solar panels to the roof and the rail</ p>

At the beginning of the installation, screws are installed in the pitched roof. The installation of screw screws is determined taking into account the load-bearing elements of the roof, with a pitch of no more than 1500 mm. The hole in the roof from the screw-screw is sealed with a complete gasket, which is pressed against the roof surface

nut. A complete nut is placed on the threaded part of the screw screw in order to further install the guide profile on it. After mounting the support profile, it is attached to the screw-screw with the second complete nut.

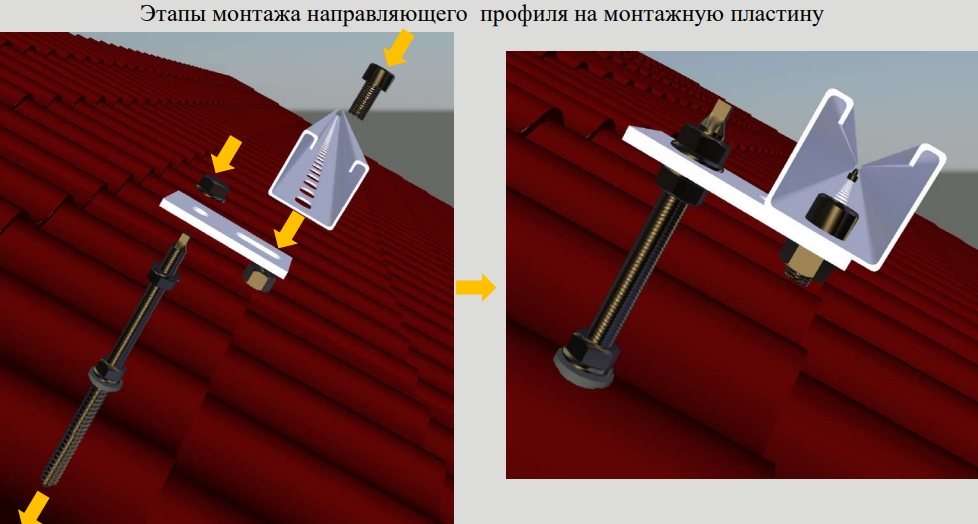

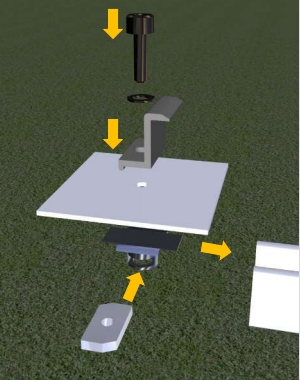

If the guide profile is offset relative to the supporting elements of the pitched roof, a mounting plate is used, which is fixed to the screw-screw. The guide profile is screwed into the oval hole of the mounting plate at the required distance.

Two guide profiles for installing a row of solar panels are installed at a distance of no more than 1050 mm from each other. The distance between the guide profiles of adjacent rows must be at least 650 mm.

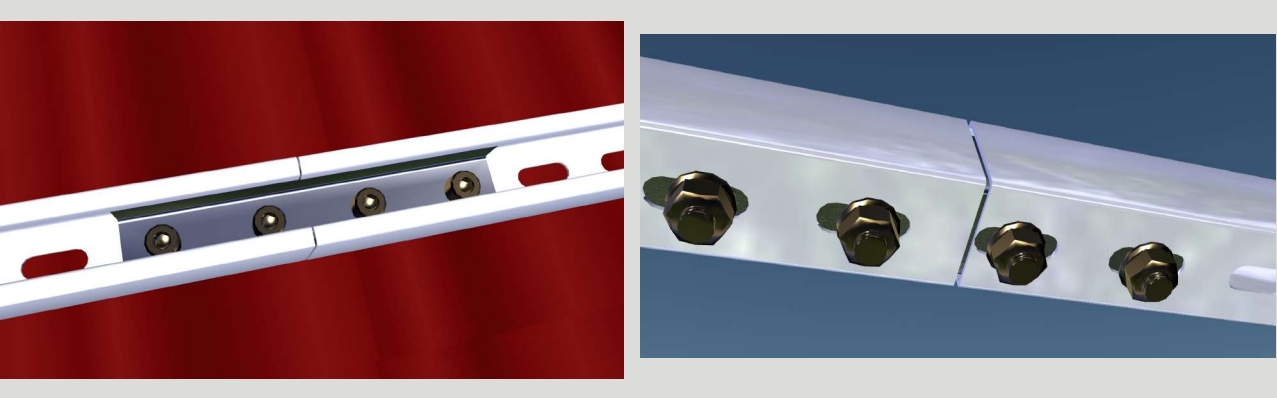

If it is necessary to connect the guide profile, a profile connector is used, which is fastened with M10 screws.

Stage 2: install solar panels on pitched roof rail< /p>

Edge solar panels are fastened using edge fixing parts. After installing the panel into the edge fixing elements, the fastening screws are tightened, fixing the solar panel.

The second and subsequent solar panels are connected to the guide profile and to each other with the help of inter-module fasteners.