sonyachnі stantsії

near the Dnipro region

→ Guide profile 41x41x9x8x1.5 mm – hot-dipped galvanized steel 50-70 microns, cold-galvanized steel 25 microns;

→ Brackets – hot-dip galvanized steel 50-70 microns;

→ Hardware for fastening the structure – galvanized steel;

→ Clamps – aluminum AD-31;

→ Gaskets – composite aluminum;

→ Hardware fastening modules – stainless steel A2.

| Material of manufacture | Super-OPT | OPT | Retail |

| Hot zinc ULTRA | 950 | 1000 | 1050 |

| cold zinc | 850 | 900 | 950 |

*prices are indicated in hryvnias

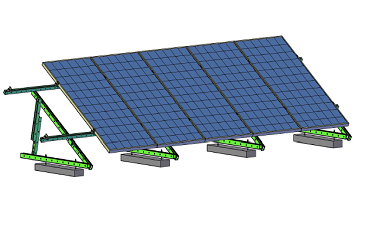

→ Sidewalk curb 1000*250*80 mm – concrete;

→ Guide profile 41x41x9x8x1.5 mm – hot-dipped galvanized steel 50-70 microns, cold-galvanized steel 25 microns;

→ Brackets – hot-dip galvanized steel 50-70 microns;

→ Hardware for fastening the structure – galvanized steel;

→ Clamps – aluminum AD-31;

→ Gaskets – composite aluminum;

→ Hardware fastening modules – stainless steel A2.

| Material of manufacture | Super-OPT | OPT | Retail |

| Hot zinc ULTRA | 910 | 955 | 1000 |

| Cold zinc | 810 | 855 | 900 |

*prices are indicated in hryvnias

Mounting solar panels on a flat roof should perform the following tasks:

– securely fasten the PEM, preventing drift from a powerful wind;

– create the optimal angle of inclination, for maximum performance and efficiency of solar panels.

Solar panels are mounted on a flat roof with oxidation-resistant materials:

– stainless and galvanized steel;

– anodized aluminium.

The KREPMETAL company sells a mount for solar panels, with which photocells on a flat roof will be securely fixed and will last for many years.

Advantages of mounting system for solar panels on a flat roof:

– the optimal angle of inclination of the solar panels ensures maximum efficiency of the solar power plant;

– universal, as they are suitable for mounting solar panels of various configurations and power;

– wear-resistant and durable;

– light and safe.

You can buy mounting systems for vertical mounting of solar panels on a flat roof from us at a competitive price. We deliver to any point of Ukraine.

The ULTRA Hot Dip Galvanized Solar Flat Roof Mounting System is a certified anti-corrosion hot dip galvanizing according to ISO1461:2009.

This coating provides protection against corrosion for metal products made of steel for more than 30 years. Profiling is performed, and then perforation. The finished profile is immersed in a hot zinc bath, hence the name “hot galvanized”.

The result is a monolithic and continuous treatment of the entire surface of the profile with hot zinc – this treatment method guarantees maximum protection from the effects of the external environment and a long service life of the solar panel mounting system on a flat roof.

– Guide profile – 08ps steel, structural carbon steel, hot-dip galvanized coating 50-70 microns thick = 800-900 grams of zinc per 1 sq.m. metal;

– Clamps for fastening modules – aluminum;

– Brackets – hot-dip galvanized steel;

– Construction hardware – hot-dip galvanized steel;

– Insulating gaskets – composite aluminum;

– Hardware of aluminum clamps for fastening modules – stainless steel A2.

Cold-galvanized flat roof mounting system for solar panels: is made from pre-galvanized metal, profiling then perforated, and as a result, all holes and ends of the profile are uncoated and corroded accordingly.

– Guide profile – Steel 08ps + ZN275 zinc coating 25 microns = 275 grams of zinc per 1 sq.m. metal;

– Clips of fastening of modules – aluminum;

– Brackets – Galvanized steel;

– Construction hardware – Galvanized steel;

– Insulating gaskets – Composite aluminum;

– Hardware of aluminum clamps for fastening modules – Stainless steel A2.

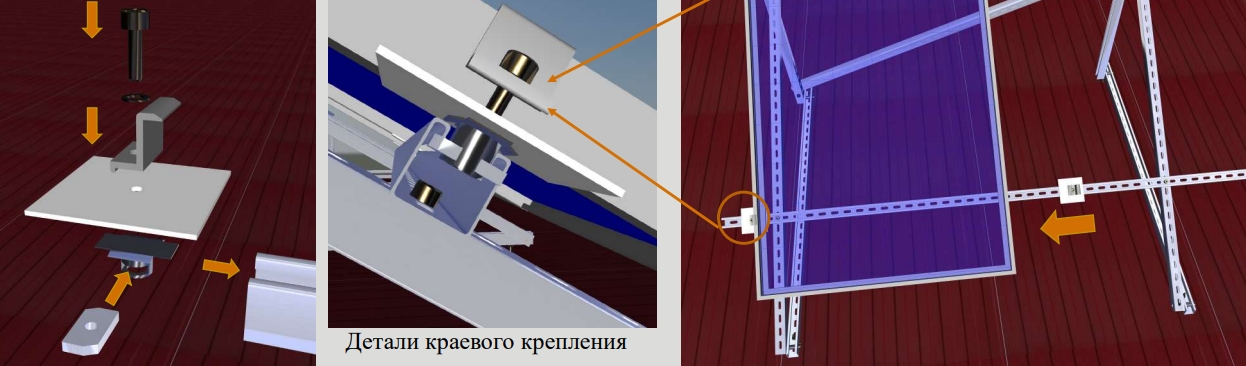

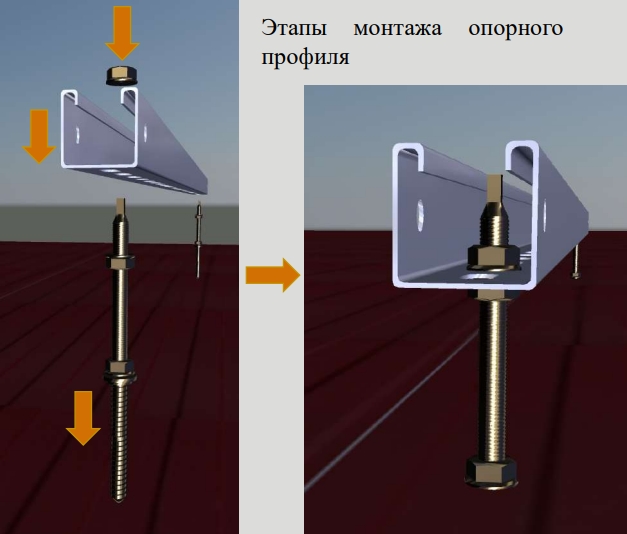

Stage 1: attaching the support profile to the flat roof

At the beginning of the installation, screws are installed into the flat roof. The installation of screw screws is determined taking into account the load-bearing elements of a flat roof. The hole in the roof from the screw-screw is sealed with a complete gasket, which is pressed against the surface of the flat roof with a nut. A complete nut is placed on the threaded part of the screw screw in order to further install the support profile on it. After mounting the support profile, it is attached to the screw-screw with the second complete nut.

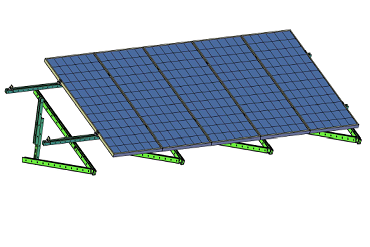

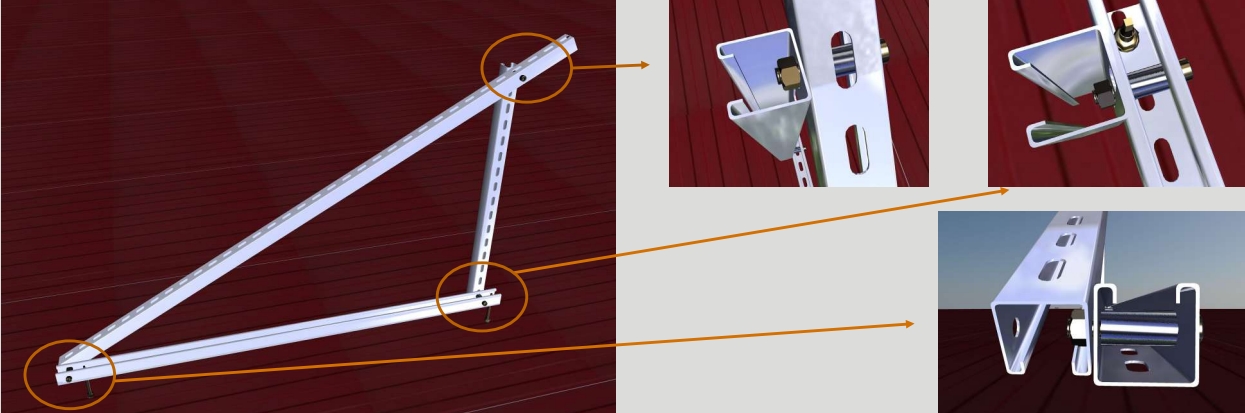

Step 2: mounting support triangles to flat roof

A triangular frame is made on each of the supporting profiles, the frame parts are attached to each other with M10 hex screws, the screws are installed in the provided holes. For structural rigidity, a pipe spacer is installed when installing the screw.

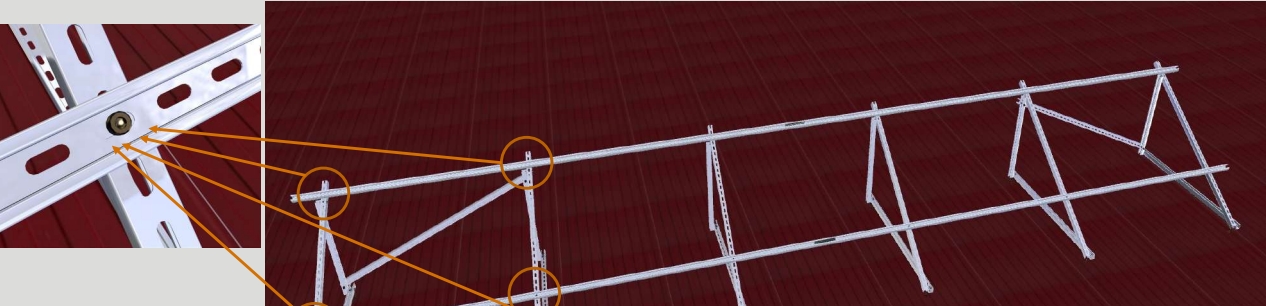

Step 3: Set Guide Profile

Two guide profiles for solar panels are installed on the support triangle. The profiles are fastened to the triangles with M10 screws through the perforation.

Stage 4: mounting solar panels on the roof on the guide profile</ p>

Edge solar panels are mounted using edge mounting parts. After installing the solar panel into the edge fixing elements, the fastening screws are tightened, fixing the solar panel.